|

Henan Fote Heavy Machinery Co., Ltd.NO.1

|

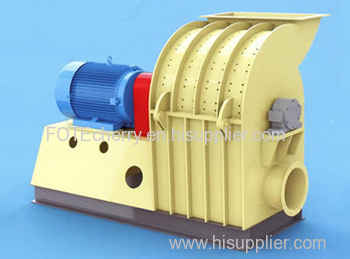

Hammer Mill for Hot Sale/Hammer Mill Manufacturer

| Price: | 10000.0~100000.0 RMB |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hammer Mill for Hot Sale/Hammer Mill Manufacturer

To process supreme-quality feed for animal husbandry and aquaculture, you should take into consideration crushing system as well besides the core machine feed mill or feed pellet mill within a complete feed making production line. Because raw material before conveyed into feed mill should be pretreated well in view of the influential factors such as moisture content, size and different recipes for different animals.

Features of Hammer Mill for Hot Sale/Hammer Mill Manufacturer

1. Raw Material Type: hammer mill for feed making is seen as the important equipment to crush raw material to a suitable size. The crusher can handle feedstock such as corn, cotton, cotton seeds waste, bean waste, wheat straw, corn stalk and oil cake extracted from oil plants;

2. Prolonged Service Life of Hammers: aligned groups of hammers as the main crushing components in the crusher chamber can be changed way easily; thanks to the adoption of corrosion-resistant steel material, the hammer mill crushing plates can even be used on single corner for a longer time compared with other crushers;

3. Iron Net Mesh: the crushing system can achieve high efficiency for processing forage material. For instance, 95% of materials can get through 60 meshes without blockage. When the iron screen vibrates, the efficacy can be enhanced by 20%-30%. We may take corn (with moisture content of 13%) as example for your reference.

4. Elegant Design: the hammer mill for hot sale/hammer mill manufacturer generally wear a water droplet appearance with elegance; the sliding door flanked on the two sides can save floor space and facilitate maintenance; reversible guide plate installed under the inlet opening can be adjusted to fit with the adjustable rotating direction of hammers in a bid to maximize and prolong the service life of hammers;

5. Convenient Maintenance: the simple structure and good-quality corrosion-resistant steel material of crushing parts will make maintenance easier. The hammers, namely crushing plates, have four right-angle corners with two of them can be used to pulverize material. Due to the one-way revolving direction of the motor, just one corner of a hammer bear the strongest crushing impact during work.

Working Principle of Hammer Mill for Hot Sale/Hammer Mill Manufacturer

Prior to the input of feedstock, please ensure the machine has been placed on a flat ground and the no-load test run has been done for ensuing running safety, during which the rotating direction of motor shall be confirmed right in line with the entire process of feed manufacturing within a feed production line. Otherwise, please change the wire connection of motor. The two doors should be shut tightly in case of human injury. The guide plate of feedstock should be adjusted so that the material can be put inside smoothly. The function of the guide plate actually is to ensure material can be guided into crushing chamber. Feedstock will be pulverized in the water droplet chamber under the powerful impact of hammers and then collide with screens amounted against the two doors. Material will not be thrown through screen meshes until the size of it corresponds to that of the screen mesh and then sucked into next section by cyclone pipe tightly connected with the hammer mill outlet.

Contact Infomation

Email: info@sinoftm.com

Website: http://www.paradisedivingasia.com/equipment/hammer-mill.html

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China